Solenoid Coils

Our Products

- Description

- Benefits

- Certification For Solenoid Coils Enclosure

- Diagram & Dimesion

Coil Information

Coil Type:

Epoxy Moulded With LED Din Connector, Metallic Round Shape With Lead Wire Continuous Duty, IP-67 Flame Proof Coil Enclosure, IP-68 Weather Proof Coil Enclosure

Coil Bore Diameter:

8mm, 10mm, 14mm, 16mm, 18mm, 30mm

Class:

H-Class, Weather Proof IP-68, Flame Proof IP-67

Voltage \ Watt:

| 24AC | 110AC | 230AC | 12DC | 24DC |

| 7W | 8W / 30W | 8W / 17W / 30W | 10W / 30W | 11W / 30W |

Duty:

100%

Main Features:

Surge Suppressors for High Wattage Coil.

90% Power saver series also available, Latching Coil.

Latching Coil Benefits:

Remote or Battery operated application A situation where a valve needs to be open/actuated for an extended period of time When heat rise occurs from the coil being constantly energized to maintain its position is an unacceptable side effect in your application. End connections in Flame Proof Coils are available in – ½” NPT – ¾” NPT – M20 X 1.5

We Are Introducing New Power Saver Series (VA Series) Served by Our R&D Department, This New Latest Technology Saves Up to 90% of Power.

- Reduce Battery Drain

- Reduce Wiring Cost

- Reduce Temperature Rise

- Energy Savings

- Improve Valve Performance at High Pressure

- Low Wattage

Certificates For Solenoid Coils Enclosure

- Weatherproof coils are conforming as per IE/IEC-60529-2001 (Approved by ERDA) (IP-67).

- Flame Proof Coils conforming as per Is/IEC-60079-1:2007 (Approved by CIMFR).

- Coils are suitable for IIC Atmosphere Condition (Zone 1&2 Gas Group).

- Flame Proof Series are followed under BIS.

- For Flame Proof Condition Working Environment Coils are licensed under PESO.

Benefits

We Are Introducing New Power Saver Series (VA Series) Served by Our R&D Department, This New Latest Technology Saves Up to 90% of Power.

- Reduce Battery Drain

- Reduce Wiring Cost

- Reduce Temperature Rise

- Energy Savings

- Improve Valve Performance at High Pressure

- Low Wattage

Certificates For Solenoid Coils Enclosure

- Weatherproof coils are conforming as per IE/IEC-60529-2001 (Approved by ERDA) (IP-67).

- Flame Proof Coils conforming as per Is/IEC-60079-1:2007 (Approved by CIMFR).

- Coils are suitable for IIC Atmosphere Condition (Zone 1&2 Gas Group).

- Flame Proof Series are followed under BIS.

- For Flame Proof Condition Working Environment Coils are licensed under PESO.

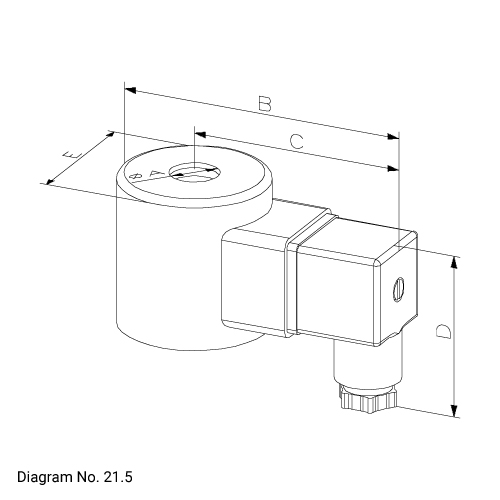

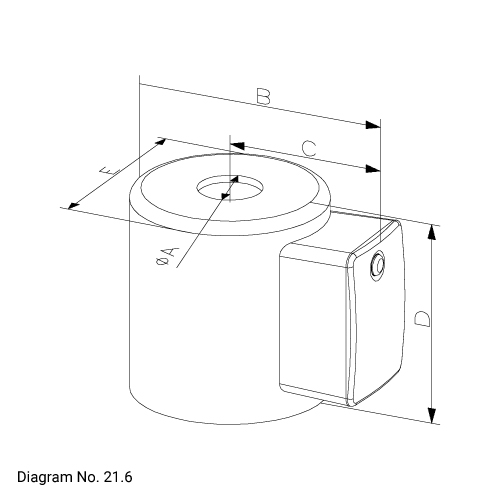

Diagram & Dimension

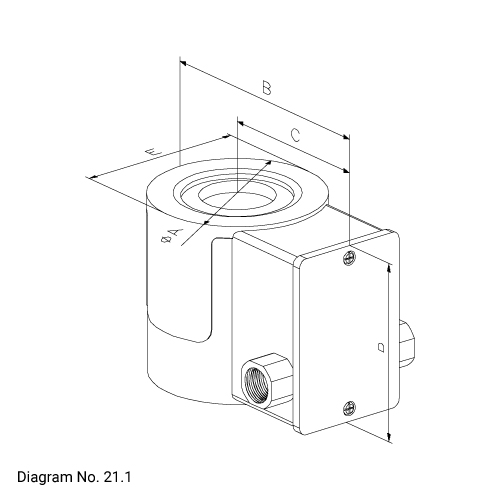

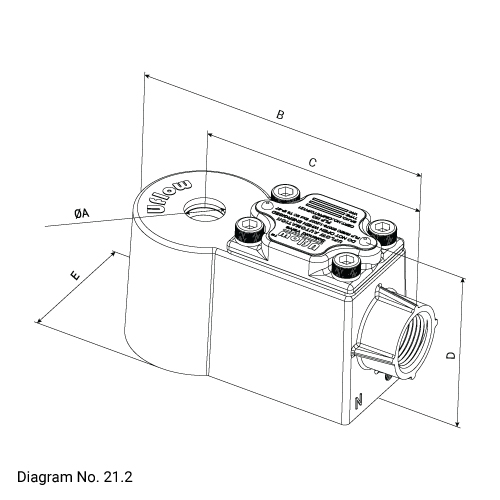

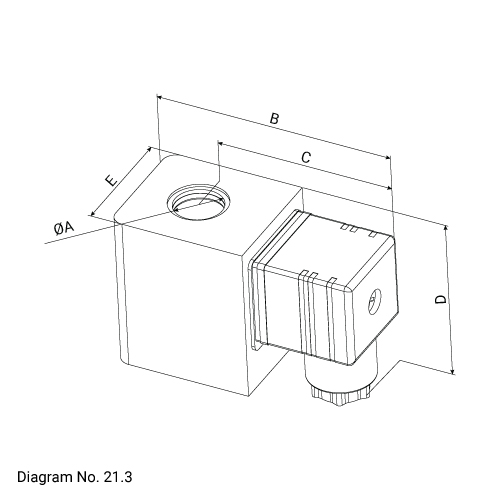

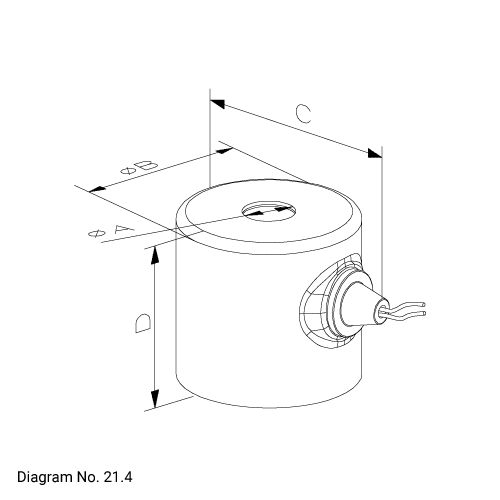

| Type | Diagram No. | A | B | C | D | E |

|---|---|---|---|---|---|---|

| Epoxy Moulded Round Coil | 21.1 | 30.50 | 105 | 69 | 75 | 71 |

| Flameproof Coil Enclosure | 21.2 | 14.50 | 112 | 86 | 62.50 | 52 |

| Epoxy Moulded With LED Din Connector | 21.3 | 14.50 | 71 | 53 | 49 | 35.50 |

| Epoxy Moulded With LED Din Connector | 21.3 | 10.30 | 65 | 52 | 46 | 26 |

| Metallic Round Shape With Lead Wire | 21.4 | 14.50 | 44 | 57 | 47.50 | – |

| Metallic Round Shape With Lead Wire | 21.4 | 10.30 | 28 | 33.5 | 30 | – |

| Metallic Round Shape LED Din Connector | 21.5 | 14.50 | 85 | 62.50 | 50 | 44 |

| Epoxy Moulded With LED Din Connector | 21.3 | 18.50 | 84.2 | 57 | 58 | 54 |

| Metallic Round Shape With Lead Wire | 21.4 | 18.50 | 50 | 62 | 60.50 | – |

| Metallic Round Shape Power Saver | 21.6 | 14.50 | 61.30 | 39 | 49.00 | 44 |