Lubricator

Our Products

Menu

- Description

- Technical Specifications

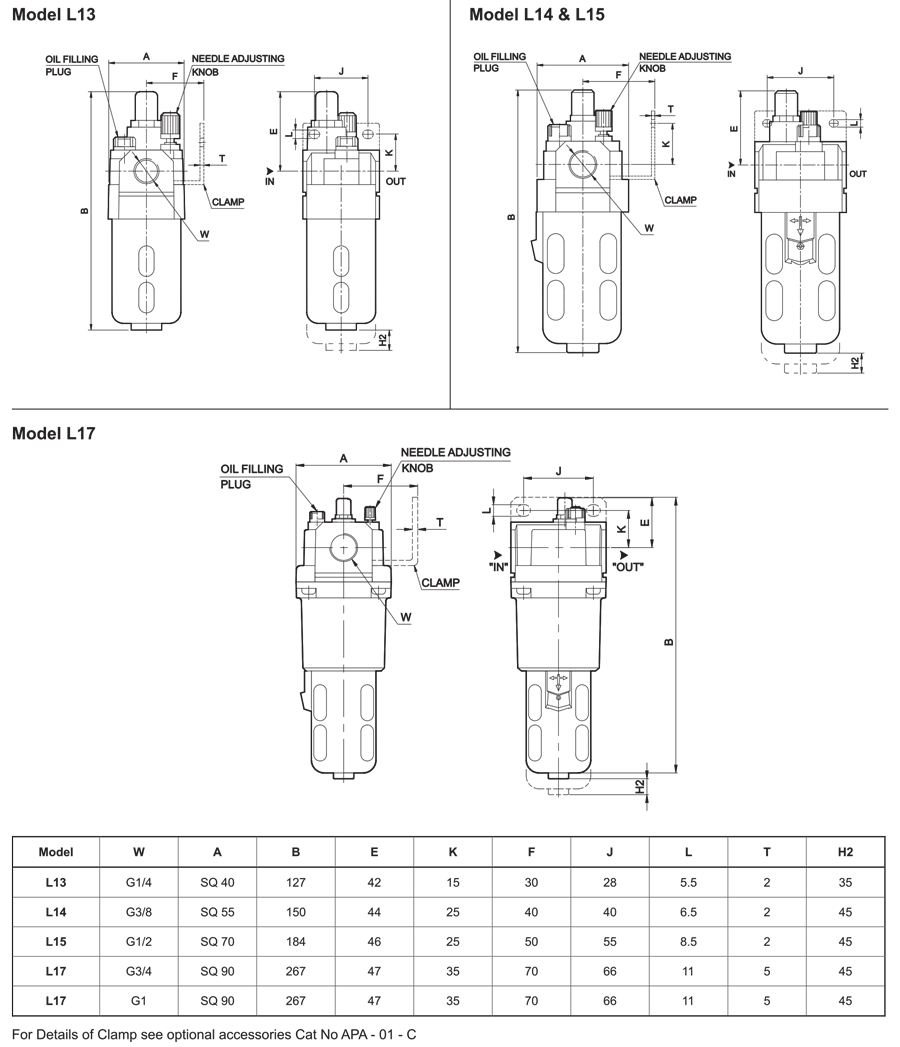

- Dimension

- Flow graphs

- Precautions

- Principle of Operation

- How to Order

L1 series – Sizes : G1/4, G3/8, G1/2, G3/4, G1

- Conform to ISO 6301-1

- Suitable for Modular mounting

- Fog/Mist type

- Fine adjustment of lubrication

- Steel bowlguard, bayonet type on L14, L15 & L17 models and threaded type on L13 model

- Lubrication proportional to flow

- Note the direction of flow before installation and connect piping accordingly

- Flush pipings for dirt, dust, rust and other foreign particles

- Install in clean atmosphere

- Nipples of taper threads ( R ) to be used with teflon tape. Ensure teflon tape does not enter the unit during tightening. Nipples of straight threads ( G ) to be used with sealing washer

- Polycarbonate bowls may get damaged and possibly fail if exposed to synthetic oils, thinner, solvents, trichloroethylene, kerosene or other aromatic hydrocarbons

- Oil may be filled when under pressure. However it is recommended to vent the air completely before filling the oil.

A part of the air entering the lubricator through “IN” pressurises the bowl chamber.

Flow of full air goes through “OUT” deflecting the “Deflector” and creating pressure drop below the sight dome.

The pressure in the bowl presses the oil through the suction tube and the oil flows through the sight dome. All the oil drops seen through the sight dome mixes with the main – stream air and come through “OUT”. The required oil drops can be adjusted by the adjusting needle.